Durable wood products extend the time of carbon stored in harvested wood and provide additional carbon benefits when replacing carbon-intensive fossil-based materials. We develop advanced life cycle models that integrate forest dynamics with the manufacturing, use, and end-of-life of durable wood products. The goal of our research is to identify science-based strategies for maximum system-wide carbon benefits.

Wood Products as Sustainable Materials - Dr. Yao’s Presentation in the Seminar Series of The Future of Wood Building Products in a Changing Climate

A new project supported by Yale Planetary Solutions Project seed grant!

Using innovative wood products to replace carbon-intensive materials such as steel and concrete is a nature-based solution to climate change and global resource challenges. However, concerns about the impact of wood products on forest carbon stock and ecosystems is a major barrier to their wide adoption. This project will develop an integrated assessment tool to help evaluate the net carbon consequences of innovative wood products across their lifecycle (from forests to wood product manufacturing, use, and end of life) and the effect on ecosystems when new wood products are adopted at a large scale. This can assist in policy and decision-making and may also support biodiversity through its study of ecosystems.

Turning Wood to Plastics, our work is on the news!

Clik here for details. The work is published in Nature Sustainability.

Dynamic life cycle carbon and energy analysis for cross-laminated timber in the Southeastern United States

Life Cycle Assessment (LCA) has been used to understand the carbon and energy implications of manufacturing and using cross-laminated timber (CLT), an emerging and sustainable alternative to concrete and steel. However, previous LCAs of CLT are static analyses without considering the complex interactions between the CLT manufacturing and forest systems, which are dynamic and largely affected by the variations in forest management, CLT manufacturing, and end-of-life options. This study fills this gap by developing a dynamic life-cycle modeling framework for a cradle-to-grave CLT manufacturing system across 100 years in the Southeastern United States. The framework integrates process-based simulations of CLT manufacturing and forest growth as well as Monte Carlo simulation to address uncertainty.

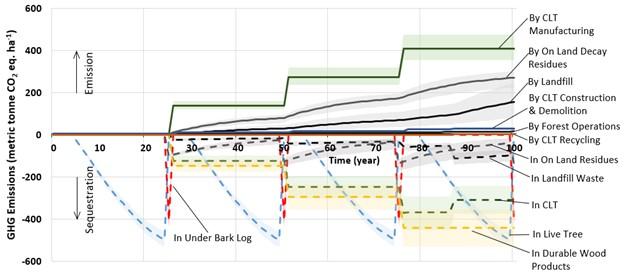

Figure 1. The dynamic carbon flows associated with the forest and the life cycle of cross-laminated timber (CLT) in 100 years for a 1 hectare, equivalent to 10,000 m2, of forest land

On 1-ha forest land basis, the net greenhouse gas (GHG) emissions ranges from -954 to -1445 metric tonne CO2 eq. for a high forest productivity scenario compared to -609 to -919 metric tonne CO2 eq. for a low forest productivity scenario. All scenarios showed significant GHG emissions from forest residues decay, demonstrating the strong needs to consider forest management and their dynamic impacts in LCAs of CLT or other durable wood products (DWP). The results show that using mill residues for energy recovery has lower fossil-based GHG (59%–61% reduction) than selling residues for producing DWP, but increases the net GHG emissions due to instantaneous release of biogenic carbon in residues. In addition, the results were converted to 1 m3 basis with a cradle-to-gate system boundary to be compared with literature. The results, 113–375 kg CO2 eq./m3 across all scenarios for fossil-based GHG emissions, were consistent with previous studies. Those findings highlight the needs of system-level management to maximize the potential benefits of CLT. This work is an attributional LCA, but the presented results lay a foundation for future consequential LCAs for specific CLT buildings or commercial forest management systems.

Lan, K., S., Kelley, S., Nepal, P., and Y. Yao* (2020). Dynamic Life Cycle Carbon and Energy Analysis for Cross-Laminated Timber in the Southern U.S. Environmental Research Letters. https://doi.org/10.1088/1748-9326/abc5e6